In his latest profile of cycling manufacturers in Germany, Josh Meissner takes us on a tour of Tout Terrain, which has been designing and assembling expedition-ready bicycles for world travelers since 2005. Despite no sparks flying on their lean shop floor, the extensive engineering that goes into these singularly rugged touring bikes turns out to be well worth a closer look…

With additional photos by Lucas Winzenburg

For my company profiles, I gravitate toward local manufacturers to which I have some prior connection. But in the case of Tout Terrain, a touring bike brand from the south of Germany, I accepted the assignment with little to go on. Lucas and I got to ride their Outback on a week-long jaunt through the Vosges Mountains in France, and they performed admirably on this short trip. In terms of objective quality, Tout Terrain bikes may well be among the best currently made. But I didn’t love the bike. The austere, industrial-looking frame just didn’t resonate with me.

Additionally, Tout Terrain frames aren’t manufactured in Germany. They’re made in Taiwan and Vietnam. That’s not a knock against them, but I wondered if I’d committed to writing about a couple of guys dispatching cardboard boxes from a warehouse. While they highlight their local manufactory in Gundelfingen, near Freiburg, I worried it was a PR gimmick. Luckily, there was a lot more happening on the shopfloor than we expected, despite no sparks flying.

Warm Welcome

Starting our tour in Wissembourg in the north, we traversed the northern Vosges mountains, following the signs of the Traversée du Massif des Vosges (TMV) route south until descending into the Rhine Valley at Sélestat. Our bags bulging with a last score of pains aux raisins and tartes à l’oignon , we crossed the floodplains and the Rhine. The signs switched to German, but the timber-framed houses stayed the same. It was hot, not only for October, and we were sweating climbing the Kaiserstuhl salient, which offers a commanding view over the plain and Freiburg. Paved cycle paths past orchards and vineyards took us to the small town of Gundelfingen, where we found Tout Terrain’s orange three-story building in an industrial zone on the outskirts. We dropped our thoroughly mudded bikes in their bike shed (thank you!) and took the tram into Freiburg for a shower and some pizza.

Back in Gundelfingen the next morning, we were received by Stephanie. She asked how we got here and whether the bikes were good. The meeting room in the second story is painted in a friendly orange, too; it seems to be their color. Beyond a few prints of travel scenes and rim-brake Tout Terrain bikes hanging off the walls, the space is very clean. As Stephanie gave us the backstory on the company and the bikes in the room, it clicked with us that she was the co-founder. Her husband Oliver is the other part of the duo. The couple started the company after extended tours through Nepal and Tibet, where their existing equipment didn’t live up to their expectations. Their guiding question was, “What would the perfect touring setup look like?”

Their first answer wasn’t a bike, though. It was the original Singletrailer. They licensed the existing design by framebuilder Florian Wiesmann for series production. It’s a robust, suspended one-wheel pod that tracks well and carries a small child or the equivalent in cargo. Equipped with a wide tire and suspension, it was much better suited for their rough-road tours than the classic four-pannier setup. An updated version remains in their line-up to this day.

Florian also designed the first Tout Terrain-branded bicycle. Featuring a strong steel frame and flat handlebars, the Silkroad is a heavy-duty, German-style touring bike, of course with rim brakes and 26″ wheels at the time. The sturdy integrated rear rack reliably supports high loads with reduced odds of failure. It’s become a signature of Tout Terrain expedition bicycles. Stephanie also showed us the intriguing full-suspended Panamerica, which is no longer in their line-up.

Around 2010, they introduced their first models featuring the Pinion gearbox. Similar to the Rohloff Speedhub internal gear hub, it’s a maximalist approach to rider-centered reliability. A gearbox with a belt-drive needs very little attention while underway compared to a derailleur drivetrain. The increased reliability comes at a premium price and higher weight, and in the case of the Pinion system, a proprietary frame design. Tout Terrain has embraced this tradeoff wholeheartedly; the unique strengths of the gearbox seem aligned with their version.

They’ve branched out from their touring roots, releasing the drop-bar Scrambler, an early gravel bike, in 2009 and later the burly Outback hardtail we rode. The two models should cover most bikepacking applications. Cass reviewed the first iteration of the Outback, and we’ll be sharing our experiences with the current model in the Vosges tout de suite. I can’t think of another bike brand of this size that has made touring and bikepacking their focus to the same extent.

Besides the Scrambler, they’ve introduced the sportier Vasco and, most recently, the performance-oriented Ceres gravel bikes, the latter squarely aimed at gravel racing. They’ve also derived an “urban” line of commuter bicycles from their proven expedition frames. Nowadays, the majority of the bikes they ship out feature gearboxes or internal gear hubs and belt drives. Going with the times, wheel sizes and tire widths have increased, and V-brakes have been replaced by discs.

Starting with their original mechanic, Chris, who’s still on board, the company has been growing at a steady rate of one or two employees per year. Today, the Tout Terrain team numbers around 40 and has taken over all three floors of their original building. With her business background, Stephanie oversees operations, while Oliver takes care of strategy, brand, and development. Now with a son in tow, they tour on trails closer to home on their gravel and mountain bikes.

High Mix, High Reward

Tout Terrain ships out around 2,500 complete bicycles annually and about as many trailers. Around a quarter of the bikes are electric, and that proportion is rising. With paint and components open to customization, few bikes are configured the same. Typically, a customer places their order through a local dealer, which is relayed to the production team in Gundelfingen. The frame is painted, wheels are built, and the partially assembled bicycle is shipped to the dealer, where the customer can pick it up. Purchasing directly is also possible, but it makes up only a small percentage of orders.

The dealer model might seem antiquated in a time when many brands are going direct-to-consumer, but Tout Terrain’s dealer network is perhaps their biggest advantage. The value proposition is quality and service, not the lowest sticker price. The folks at the venerable Velophil shop in West Berlin seemed very competent and friendly when we picked up our loaner Outbacks ahead of our ride. They carried a slew of models to try out and had plenty of informational material, including a neat cut-away Pinion gearbox, which I imagine would be useful and reassuring for mainstream customers. After purchase, the dealer is the point of service in the rare case the bike needs attention.

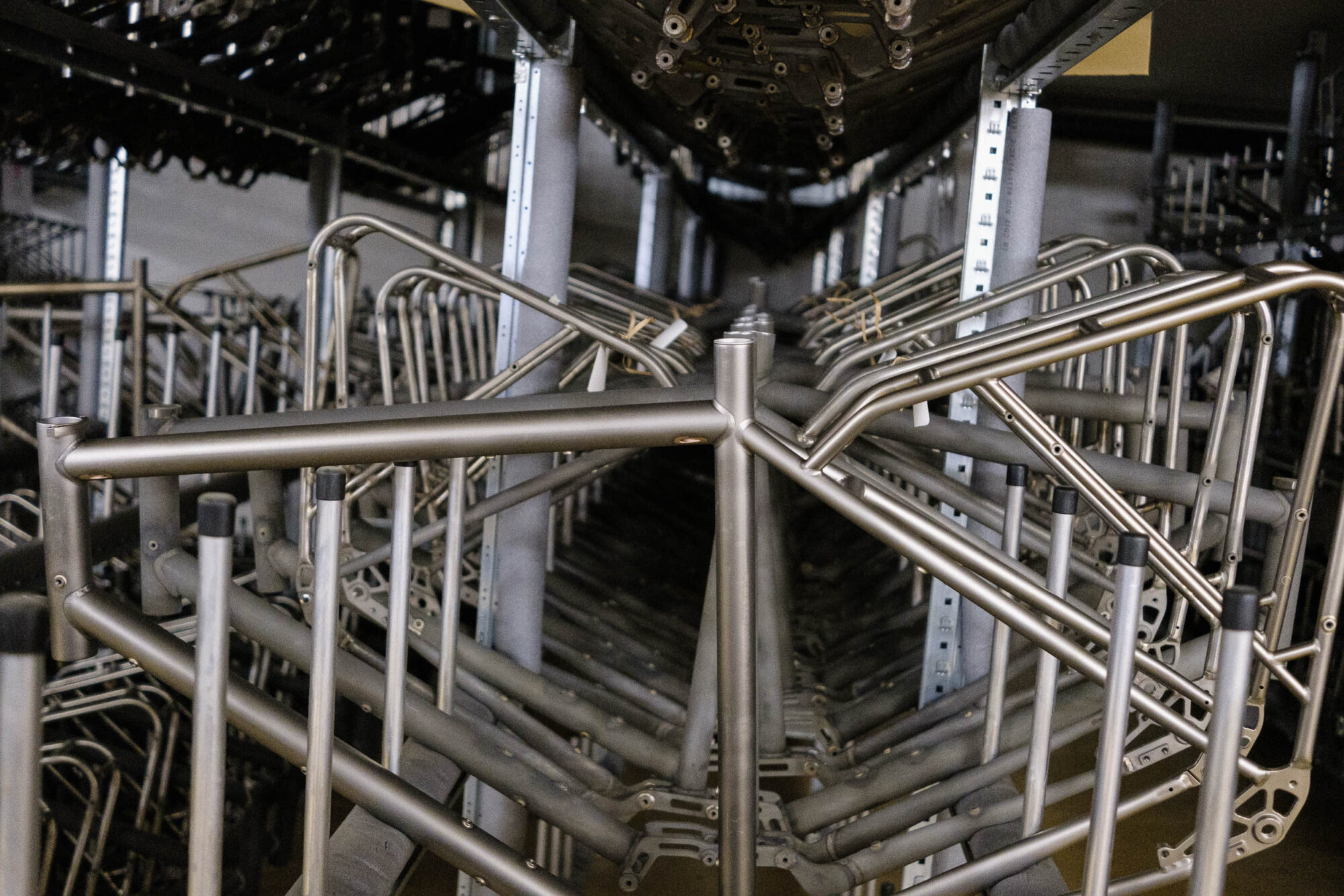

While the frames are manufactured in Taiwan and Vietnam, painting, wheelbuilding, and assembly happen in-house in Gundelfingen. Given the high degree of customization, there is simply no other way. Just their wheel versions number over 70. Production manager Patrick joined around five years ago, just before the COVID bike boom. Coming from the automotive industry, Patrick says he found the relatively lax processes and organization at the time a bit of a shock. But the small size meant flexibility—an opportunity. “In automotive, it’s very easy to say, ‘That’s not my problem.’ It’s all about adhering to the documented process, even if it’s pointless. Here, it’s more collaborative, I can talk with the decision-makers,” he explains.

The continuous improvement efforts led by Patrick over the years appear to be paying off. The facility appears notably well-organized. It’s clean and uncluttered. Colored tape on the ground marks work-in-progress, finished goods, and rework, and nothing is over the line. Kanban cards keep parts in stock, and dashboards track progress on daily, weekly, and monthly targets. Process descriptions hang at every station. The manufactory is absolutely not a PR gimmick. This is not drop-shipping out of a garage. This is a real production.

Finishing and bike assembly happen entirely on the ground floor, and wheelbuilding and trailer assembly are upstairs. The raw frames arrive in containers and are stored in the basement. Tout Terrain frames are powder-coated for durability by Thilo, a highly experienced finishing specialist. He lost me explaining the technical parameters and sequencing at this station. Powder coating is originally an industrial process, and achieving thin, even coats on batches of bicycle frames with speed and consistency is both a science and an art. Their 10-percent rework rate at this stage is very good, according to Thilo. They are currently investigating internal electro-deposition (ED) coatings for the frames, which is complicated by the integrated racks.

There are five ergonomic assembly stations in the main hall out back and four e-bike-specific stations in the front. A typical day sees about half the workstations in use. One mechanic assembles one bike, up to two per day. Lucas spoke at length with mechanic Louis on the shop floor, a young Frenchman who is about to embark on a solo tour from France to Japan. Theoretically, a complete bike could be done in two days, but that never happens. In manufacturing, waiting time typically dominates the lead time, and the aim is to reduce it. Right now, they rely on the head of assembly to coordinate the assembly work, but Patrick wants to get to a point where workers in finishing and assembly know at a glance what’s coming up next. Upstairs in the trailer assembly, mechanic Ralf enthusiastically explained how he organizes his line for efficiency.

A big challenge at this small scale is having enough people to absorb absences while ensuring that everyone has enough value-adding work throughout the year. The seasonal swings in demand for bikes are large and nearly impossible to buffer; the demand can’t be meaningfully shaped. In the past, the trailer line helped level the production to a degree, but trailer sales, in particular, have fallen after a surge during the COVID outdoor craze. Patrick encourages cross-training between roles to better respond to inevitable fluctuations. The tricky thing about effectively reducing waste in a production system is that it’s ultimately an organizational, a people issue, rarely a technological one. There’s a lot of listening and talking and mutual learning involved.

Once finished and assembled, handling and packaging are very important, as rework or damage at this late stage is very costly. Quality checks at every stage are supposed to ensure that issues are caught where they occur and not later downstream. Good packaging prevents damage en route and makes assembly simpler for dealers.

Engineering-Driven

Compared to their emphasis on lean production, Tout Terrain’s development team in the office upstairs is relatively small. As you might infer from their bikes’ pragmatic aesthetics, they are explicitly engineering-driven. “We are focused on the function. We want to make sure it works,” explains product manager Tobias. He trained as an industrial designer and has been with the company for five years, also with prior automotive experience.

“Making sure it works” in this context means the frames consistently hold up to the rigors of loaded touring. Among other things, this means testing frames in the lab over hundreds of thousands of load cycles across models and sizes and batches and changes in the design and supplier. The ISO 4210 bicycle norm provides a starting point for design, assembly, and testing, but the road and mountain bike categories don’t cover heavy touring with system weights up to 180 kilograms. There is also the question of to which degree standardized lab testing corresponds to real-world load patterns. In the end, a manufacturer is responsible for their products in the intended use and must ensure their function. The designers and engineers at Tout Terrain seem to take this responsibility very seriously. Their frames and forks are guaranteed against manufacturing defects for an above-average five years.

For their loaded touring scenario, Tout Terrain painstakingly developed their own norms and test protocols in conjunction with established German test institutes. While it would seem to simply be a case of scaling up the forces on the test rig, actually manufacturing and validating the reinforced frames is a significant and ongoing challenge. A lot of Tobias’ time is spent communicating with their frame suppliers so they can achieve Tout Terrain’s special demands: stronger frames with consistently tighter tolerances in dimensions and alignment. This requires high-grade raw materials as well as proprietary tooling, fixtures, orders of operation, and regular testing in the lab and in the real world, which all add to the cost. The frames might be overengineered and overbuilt for many use cases, but I wouldn’t say they are overpriced given the extensive engineering that goes into them.

Cycling City

Our Tout Terrain tour included a visit to the Experience Center, their showroom located nearby in the town center. Stephanie led the way on her e-cargo bike, surging ahead on a shortcut through a quiet residential area. We popped out in the modern town center with multi-story, mixed-use buildings. The Experience Center is on the ground floor, above are apartments. It’s a three-minute walk to the train station, one stop from Freiburg. Alternatively, you can hop on a bus or take the tram. Or you can ride your bike.

The bright and spacious showroom is Tout Terrain’s direct link to prospective customers and a space for workshops and events. Customers can get in touch to test and potentially ride home their dream touring bike and get after-sale service. They share the showroom with Supernova, the premium bike light manufacturer, who are their next-door neighbors in the industrial area and equip some of Tout Terrain’s models.

In fact, the Freiburg area is a cycling industry hotspot in Germany. Tune, Trickstuff, and Intend produce premium components. Cannondale has its R&D center here, as does Specialized. The well-known bike leasing giant Jobrad recently set up a big office downtown, their cushy corporate conditions pulling many employees from the smaller brands. With good public transit, extensive cycling infrastructure, walkable neighborhoods built for humans, and a pedestrianized city center, Freiburg ranks high in quality of life. International rail connectivity, sunny weather, and the Black Forest, Vosges, Jura, and Alps within cycling distance make it a viable and desirable place to live car-free, especially for families.

With 20 years of experience in designing and producing reliable heavy-duty touring bikes, cargo bikes would seem the logical next step for Tout Terrain. But Stephanie says they currently have no plans of making that leap. Cargo bikes are another world that requires specialized expertise, supply chains, and marketing. It’s a saturated segment, too. However, cargo-adjacent bikes and accessories may be in Tout Terrain’s future.

They do plan on expanding into the US market in 2025 with a local distributor, and inviting us to ride their bikes and write this article is part of that push. While the brand and bikes don’t exactly speak to me, I find it heartening that this wholesome company is part of the bikepacking ecosystem. We got the distinct impression that the folks at Tout Terrain really believe in the products they’re creating. They appear committed to their particular, coherent vision of the touring bicycle, engineering-driven design and manufacturing, and respect for bike shops, and I think those are unequivocally good things.

Further Reading

Make sure to dig into these related articles for more info…

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.